OTR Engineered Solutions rolls out new wheels

18 November 2024

Off-highway wheel designed for faster, safer tire changes

In certain applications such as mining and forestry, the equipment industry is moving toward higher ply ratings to ensure each tire stands up to tough underfoot conditions and heavy loads. Today, big tires may sport thick 38 and even 40 ply designs that can make mounting them onto traditional one-piece wheels a challenge.

“When you’re talking about a 4 or 5 in. thick piece of rubber, to get all of that to mount on the wheel means risking cutting the bead of a very expensive tire,” said Don Rowswell, vice president of Sales for Mining, Ports, & Forestry for Rome, Ga.-based OTR Engineered Solutions (OTR).

To help end-users reduce downtime and enhance efficiency, OTR recently introduced a 32-in. three-piece wheel for log skidders and forwarders used in forestry applications. The company said the multi-piece allows tires to slide on and off the rim when mounting and dismounting without the need for special equipment.

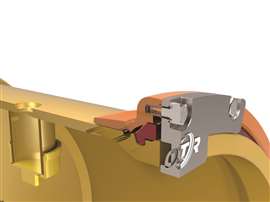

Under development for more than a year, the sections of the wheel are unbolted and the lock ring removed, allowing the tire to slide off. The company said the process minimizes the risk of bead damage since the tire does not need to be pried over the rim. It also reduces downtime.

OTR Engineered Solutions has introduced a three-piece 32 in. wheel to make changing modern heavy-equipment tires less time consuming. (Illustration: OTR)

OTR Engineered Solutions has introduced a three-piece 32 in. wheel to make changing modern heavy-equipment tires less time consuming. (Illustration: OTR)

Game changer

“The new three-piece wheel is a real game changer in the forestry industry,” said Tom Rizzi, president and CEO, OTR. “This solution can help customers increase their load carrying capacity, while simplifying the process of changing tires in the field.”

The company said the new design can also help reduce the potential for tire indexing, or spinning, on the rim. Other features are reportedly built in for improved strength, torque retention, tire sealing and durability.

Original equipment manufacturers (OEMs) as well as end-users can use the wheels to move up in ply ratings to help maximize the productivity of the machine. For example, OTR said a skidder may be able to add 28,000 to 42,000 lb. of additional tire load capacity with 40,000 to 60,000 lb. of additional headroom by upgrading to higher ply tires and its three-piece wheels.

OTR introduced the wheels at the 2024 Demo International in September, a five-day forestry equipment show held in Venosta, Quebec, Canada. (Photo: OTR)

OTR introduced the wheels at the 2024 Demo International in September, a five-day forestry equipment show held in Venosta, Quebec, Canada. (Photo: OTR)

“We’re really good at listening to customers and solving their problems, regardless of where the customer sits in the chain,” said Rowswell. “Our first-to-market 32 in. three-piece forestry wheel is a great example of that. It allows the end user to mount and dismount tires in the field a lot easier and in about 15 minutes. The best part for us is that while the wheel has been tailored to the end-user, large OEMs are already working with us, as well. They want to know what the customers are saying about having a three-piece wheel option.

“The feedback we’ve already received from customers is that when it’s raining or it’s cold, there’s a big risk of a getting hurt while changing tires and conventional rims and they just don’t want to change tires. The cost of the downtime alone is something they’ve discussed a lot.”

The three-piece wheel parallels aspects of OTR’s 32-in. single piece wheels, which the company said have been proven in harsh conditions by its OEM customers.

“There are many benefits to our three-piece wheel design,” said Rizzi, “including increased load capacity, reduced indexing, and easier tire mounting and dismounting offer huge advantages in the forestry industry. All of these individually can result in a better bottom line.”

A good listener

“I think what’s unique for us as a tire and wheel supplier is that we actually listen to the end-user,” said Rowswell. “We listen to the customer, and what gets us in the door nine times out of 10 is that they will come to us with a challenge they’re having in the field, and we will start working with them closely to offer a solution to a problem. Through that collaboration we’ll come up something that works for everyone.”

OTR currently offers the three-piece wheel in 32x27 and 32x31 configurations, compatible with 30.5L32 and 35.5L32 tires.

The company operates factories around the world, including Canada and the U.S. Most of the product development takes place in Rome and covers a wide range of off-highway equipment markets.

“The engineers in Rome are the quarterbacks of gathering the information and coming up with the innovation we have in our tire and wheel products,” said Rowswell. “Oftentimes, like with the forestry wheel, one of our sales reps will be taking input from the customer and working closely with engineering to help design, test and tweak the wheel for the application.

“That’s how we handle it in all the markets we cover, and not just forestry. In mining applications, for example, we have some new designs coming out that will really change things in that industry. That innovation is a key part of our part of our foundation as a company.”

When the sections of the wheel are unbolted and the lock ring removed, OTR said the tire will slide right off. (Illustration: OTR)

When the sections of the wheel are unbolted and the lock ring removed, OTR said the tire will slide right off. (Illustration: OTR)

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM